Coronavirus: Ashby Man With NHS Frontline Worker Aunt Is Part of PPE Production Line At JCB

By Graham Hill 17th Apr 2020

An Ashby man says he is 'proud' to be part of a volunteer team producing vital personal protection equipment for the National Health Service - particularly as his aunt is a frontline NHS nurse.

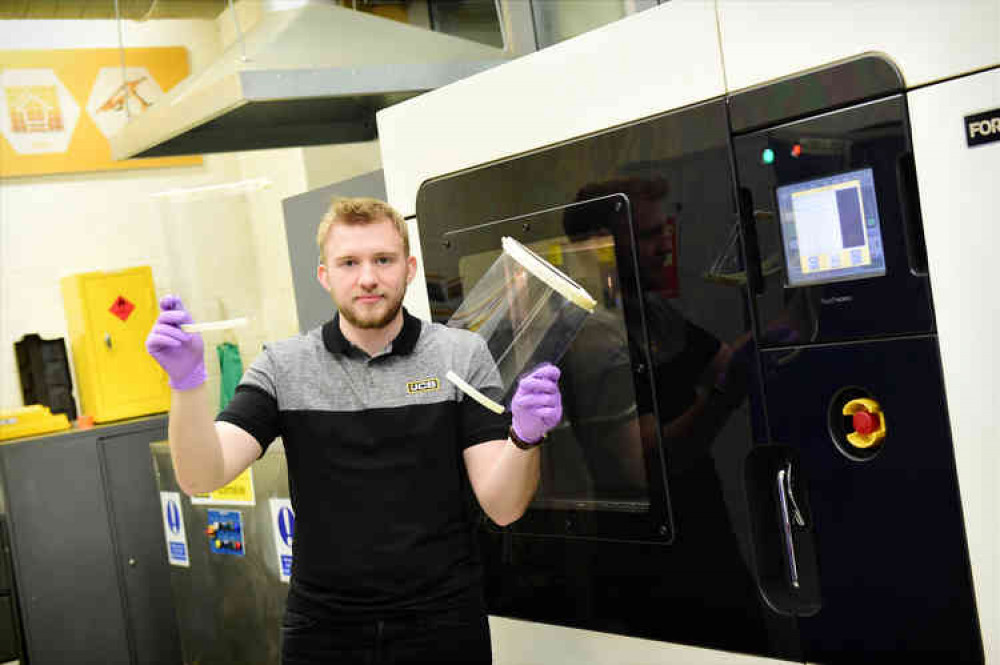

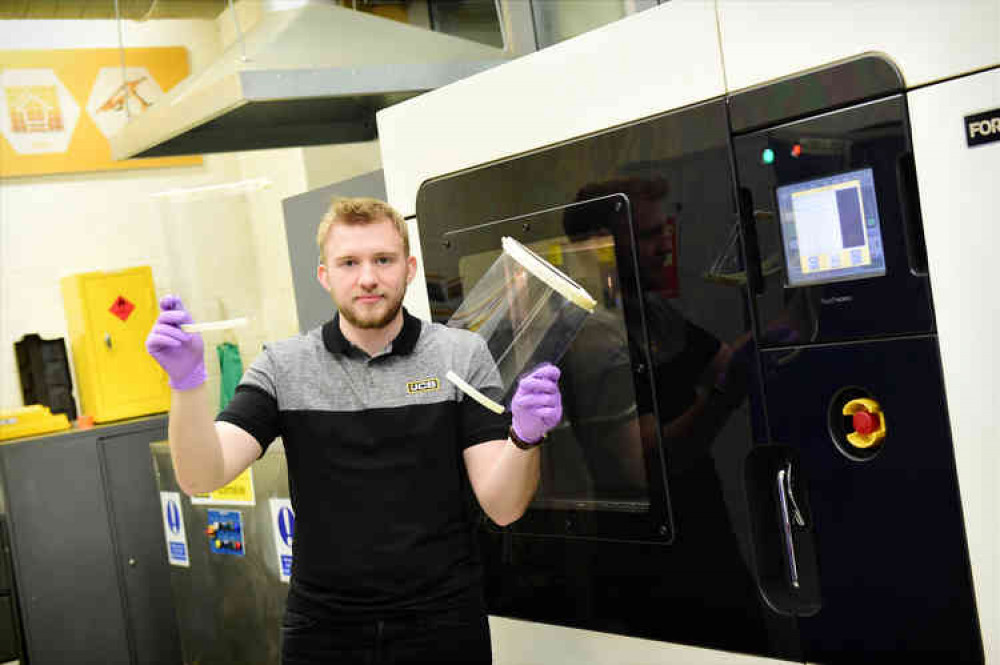

Joe Bagley, 25, is working with well-known Staffordshire company JCB on a mini-production line - and has close family ties with the NHS.

Principal Electronics Engineer and father-of-two James Morley – who is normally based at JCB's World HQ in Rocester - has converted the garage at his Derbyshire home to produce the supplies.

Inspired by his efforts, JCB has re-opened its Innovation Centre at their World HQ so colleagues and Tooling and Moulding Engineers Joe - along with Joe Mumby, 22, can have free use of the company's 3D rapid prototype machines to help produce medical grade visors for NHS staff.

Ashby-based Joe said: "I'm proud to be part of the volunteer team producing vital personal protection equipment for the NHS, particularly as I have an aunt who is working on the front line as an NHS nurse.

"It's great that JCB has opened up part of its World HQ to enable us to undertake this voluntary project as everyone in the NHS is doing a fantastic job.

"This is our way of saying a very big thank you."

For Joe Mumby, of Hilton, Derbyshire, volunteering to produce the vital NHS kit has also taken on a poignant significance as he and his family come to terms with the death of his father's cousin from Coronavirus in the past few days.

He said: "Helping with the production of visors is the least I could do as this is a very testing time for everyone, including my own family. It's fantastic that JCB has given us the opportunity to give something back to those who are the front line of the virus in what must be a very scary time for them."

So far, the volunteer production line set up at JCB has produced 50 visors for distribution to surgeries in the Rocester and Uttoxeter area with the help of material donated by the JCB Academy.

With the visor material now exhausted, Joe and Joe are concentrating their efforts on producing hundreds of head bands required for the visors before despatching them to a Warwickshire company for final assembly.

Meanwhile, Mr Morley, 43, who was the original inspiration for the project, has transformed his rapid prototyping machine in the garage of his home in Belper, near Derby from making toys for children Alice, eight and Joshua, five, to producing NHS kit.

Having made 20 visors, he is now diversifying his domestic production line to make components, which convert snorkelling masks for use with hospital ventilators.

He is also rapid prototyping so-called 'superhero nurse' headbands which make face masks more comfortable for medical staff to wear as they fit on the back of the head rather than on to the back of ears.

James says he has been touched by the generosity of people during his voluntary work – including the donation of half a kilometre of plastic for his project from one well-wisher.

He said: "While browsing social media on the state of the Covid-19 situation, I was aware that there was a huge shortage of medical grade personal protective equipment for our NHS and other healthcare communities around the UK. It made me dust off my 3D printer and help contribute to the fight against Covid-19 and support our heroic NHS.

"I am glad I can help out and make use of my printer during this national crisis and keep myself active with volunteers during the furlough period. It is amazing what support there is out there and how much people would like to help."

JCB Chief Innovation Officer Tim Burnhope said: "JCB is delighted to be able to play a role in helping provide the fantastic NHS with protective equipment. The volunteer employees who are part of this amazing effort are also to be commended for stepping up at this time of national crisis."

3D printers take Computer Aided Design data and build it into a 3D object using very fine layers of melted plastic. The plastic is heated up to around 210°C and then extruded on to a flat metal plate, that is also heated up to around 60°C.

Over the next few hours, the printer will finish the object before it is simply peeled off the flat plate and used.

CHECK OUT OUR Jobs Section HERE!

ashby vacancies updated hourly!

Click here to see more: ashby jobs

Share: